Core certification and safety assurance

The equipment has strictly passed CE and UL dual certification, and the entire process from design to production complies with international safety standards. The motion control system reaches ISO 13849 CAT3 PL-d safety level, with IP54 protection level junction box, cable clamps to prevent metal scratches, and motor cables use high-flexibility and bend-resistant wires to eliminate electrical safety risks from the source.

Motion structure: double breakthrough in precision and stability

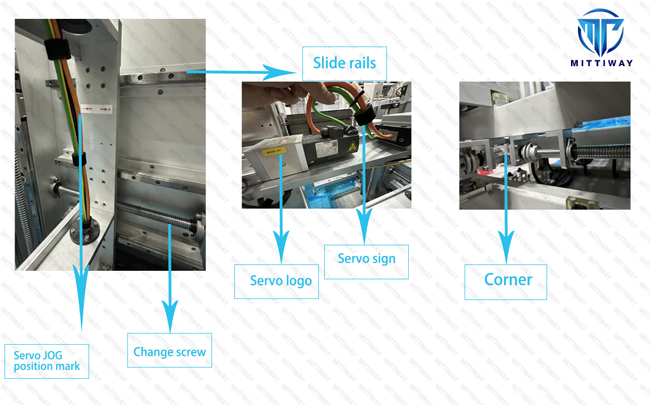

·1.Maintenance and changeover efficiency: The motor is installed outwards, and the machine does not need to be disassembled for maintenance; the servo parameter formula can be switched with one button, and the changeover time is shortened to 1/3 of that of traditional equipment.

·2.Precision transmission solution: The core moving parts are preferably ball screws to ensure ±0.05mm positioning accuracy; if belt drive is required, an open-loop belt system is standard, taking into account both cost and reliability.

·3.Heavy-duty bearing design: The material rack lifting mechanism adopts a heavy-duty slider with a load-bearing capacity of 500kg+, and runs smoothly without shaking.

Ergonomics and appearance craftsmanship: details make the experience

·一.Optimized operation interface:

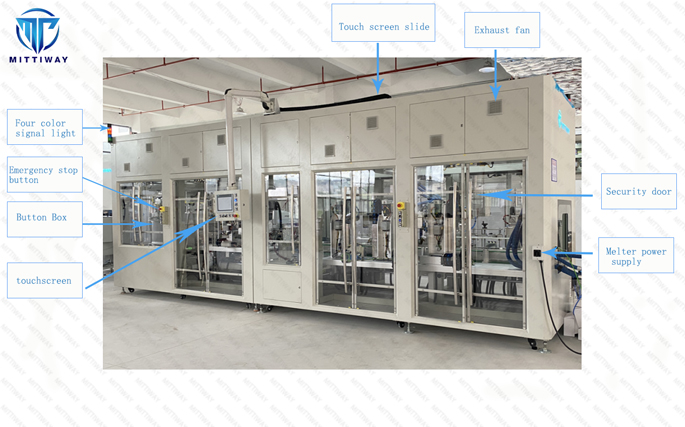

1.The cantilever touch screen is 1550mm high, ergonomic, and equipped with a horizontal sliding rail, it can cover a 3-meter operating range;

2.The emergency stop button is exposed (no cover allowed), and the response time is less than 0.5 seconds, meeting the emergency braking requirements.

·二.Safety protection system:

1.The safety door switch is fixed with anti-theft screws, dual-circuit design + STO kinetic energy cut-off function, and the machine will stop within 0.1 seconds when the door is opened abnormally;

2.The button box spacing is 1.2-5 meters evenly distributed, the touch height is 1.8 meters, and IP65 waterproof and dustproof buttons are used.

·三.Machining process standards:

1.The edges and corners of the sheet metal parts are enlarged R4-5mm rounded and electrolytically polished, without burrs and will not hurt your hands;

2.The aviation plug has an IP67 waterproof rating and 10G vibration resistance, and the equipment is split for easy transportation and installation.

Electrical and pneumatic systems: integration of intelligence and reliability

·一.Electrical control:

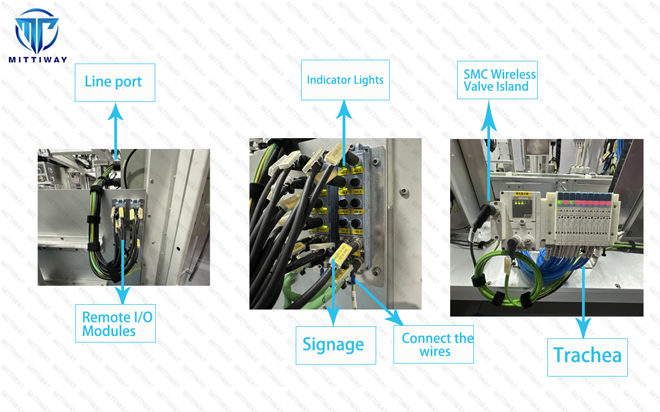

1.Remote I/O modules support long-distance communication of hundreds of meters (optical fiber/industrial twisted pair), solving the wiring problem of complex production lines. The port status indicator shows the fault in real time, and the maintenance efficiency is improved by 40%.

·二.Pneumatic solution:

1.Adopt SMC wireless valve island, wireless communication replaces traditional wiring, and integrates multiple solenoid valves to realize centralized control of pneumatic system;

2.The material taking mechanism is equipped with anti-twist regulating valve, and the cylinder fixing seat is designed with grooves, so that no tools are required to replace accessories;

3.The air source treatment adopts Festo five-piece, with a filtration accuracy of 5μm to ensure the life of pneumatic components.

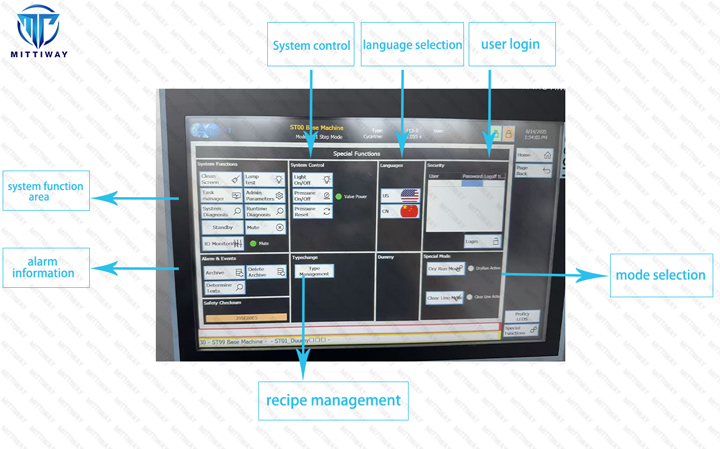

Touchscreen

Hot melt adhesive system: Nordson technology enables precise glue coating

1. Nordson ProBlue Flex hot melt adhesive machine is standard, with three anti-pollution designs:

1. The glue tray at the bottom of the nozzle prevents dripping and contamination;

2. The glue grid on the opposite side prevents glue mist from splashing on the glass/human body;

3. The Teflon coating translation mechanism prevents scratching the surface of the paper box, and the glue coating accuracy reaches ±0.1g.

Summary of the advantages of the whole line

1. Safety and compliance: CE/UL/JIS certification + CAT3 PL-d safety level, adapted to global

market access requirements;

2. Efficiency improvement: one-button changeover, wireless valve island and other designs, single-shift production capacity is 30% higher than traditional equipment;

3. Durability: ball screw + heavy-duty slider + electrolytic polishing process, the whole machine life exceeds 100,000 hours;

4. Humanized design: ergonomic operation interface + full-wrapped safety protection, reducing worker operation fatigue and risk.

Applicable scenarios: Full-process automated production of carton forming, robot filling and sealing in the food, medicine, daily chemical and other industries, supporting customized production line layout and function expansion.